General properties

| ACQUANDAS Nitinol thin films |

Nitinol standard material | |||

|---|---|---|---|---|

| Tensile strength | 1100 – 1500 MPa | 1100 – 1500 MPa | ||

| Plateau length | 5% | 8% | ||

| Fatigue Endurance Limit (>10 million cycles at 2% mean strain) |

1.5%* | 0.5-0.6% | ||

| Feature resolution | 1 – 10 µm | 15 µm ± 5µm | ||

| Thickness & homogeneity | > 0.1 μm, < 80 μm ± 1% of nominal thickness |

> 50 μm ± 20% of nominal thickness |

||

| Corrosion | >1200 mV Break* | 1200 mV Break | ||

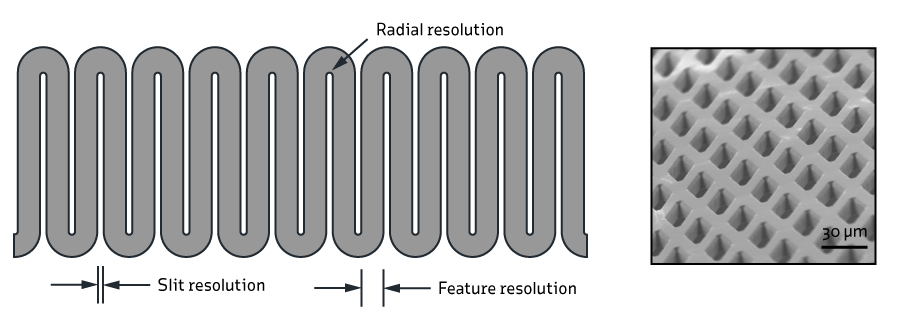

Feature resolution

| Film thickness / µm |

Feature resolution / µm | Slit resolution / µm |

Radial resolution / µm |

|---|---|---|---|

| 5 | 1 | 1 | 1 |

| 10 | 3 | 3 | 3 |

| 20 | 5 | 3 | 3 |

| 40 | 6 | 4 | 4 |

| 60 | 8 | 4 | 4 |

| 80 | 10 | 5 | 5 |

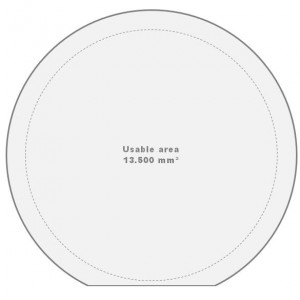

Usable areas & homogeneity

4″ (development phase, low volume)

The usable area in the development phase is restricted to 40 mm in diameter. Our development system is highly flexible and designated for rapid prototyping. Within the 40 mm diameter, the design can be freely chosen within the given properties and limitations indicated above. The thickness homogeneity is ±14% nominal thickness and the compositional homogeneity is around ±0.3at% (measured by EDX).

6″ (production phase, high volume)

In the production phase, the usable area increases to a maximum of 130 mm in diameter, concomitant with a tremendous increase in homogeneity with regards to both thickness and chemical composition. Several wafers are processed simultaneously, which makes this system suitable for high-scale production. Inside the 130 mm diameter, the design can again be freely chosen within the given properties and limitations as indicated above. The thickness homogeneity is now ±1% nominal thickness and the compositional homogeneity is around ±0.4at% (measured by EDX).

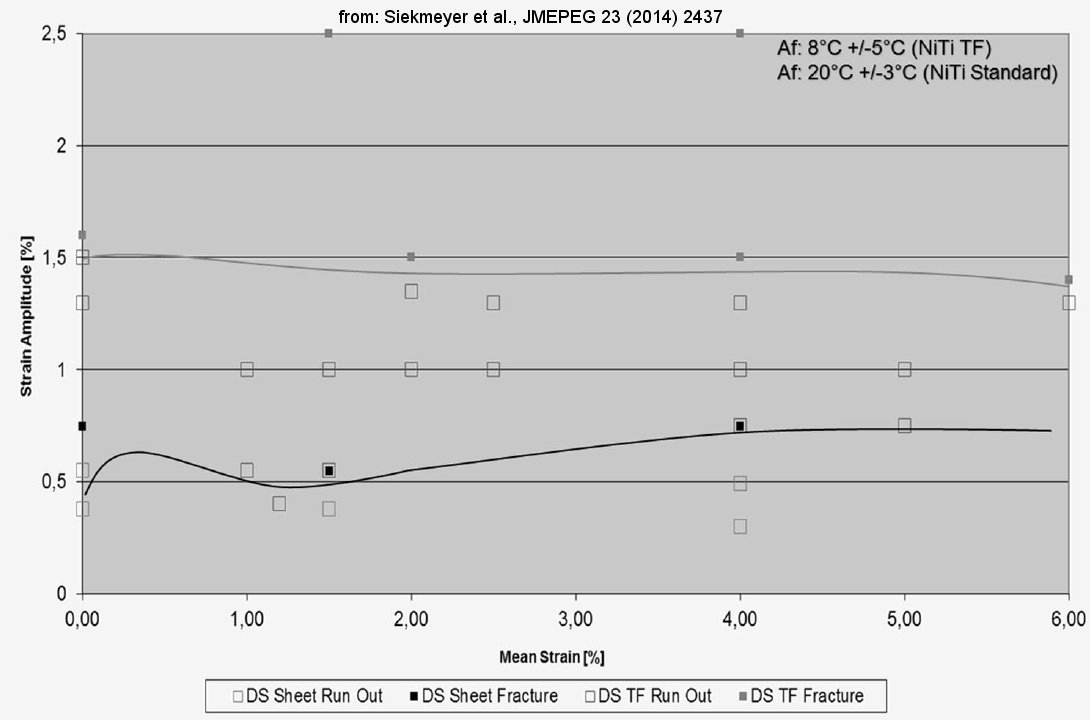

Mechanical properties and fatigue performance

Sputtered Nitinol thin films show excellent fatigue properties. Whereas standard Nitinol material reaches a safety limit of ±0.6% alternating strain, a recent study (JMEPEG 23 (2014) 2437) has shown an improved safety limit of up to three times higher for sputtered thin film material. A major reason for this increase in fatigue performance is the high purity of thin film material, completely lacking oxide and carbide inclusions and adjacent voids.