Information exchange

In the initial stages, we introduce our customers to the characteristics of our fabrication pathway and identify the specific benefits of a final thin film product. We develop a concept that optimally exploits the advantages of thin film fabrication processes.

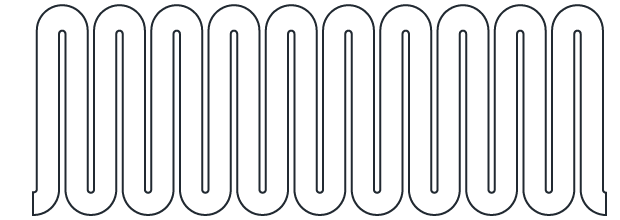

CAD

Once the characteristics of the fabrication pathway are understood, the design is adjusted so that it can be produced with excellent mechanical properties, great endurance, high quality and cost efficiency. The ACQUANDAS process then starts with a simple 2D CAD design.

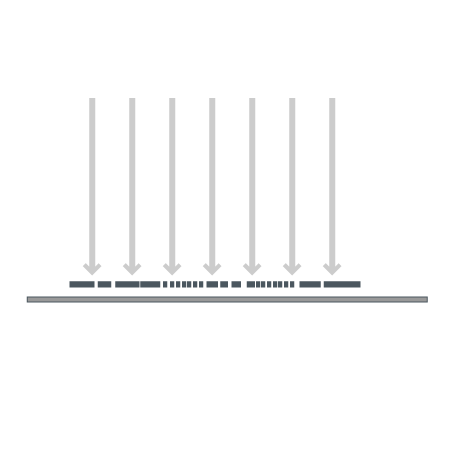

UV-Lithography

From the 2D CAD design, a UV-lithography mask (glass partly covered with Cr) is produced and used to structure a photosensitive resist. The resulting high-resolution pattern of the photoresist is transferred to the final product during the process.

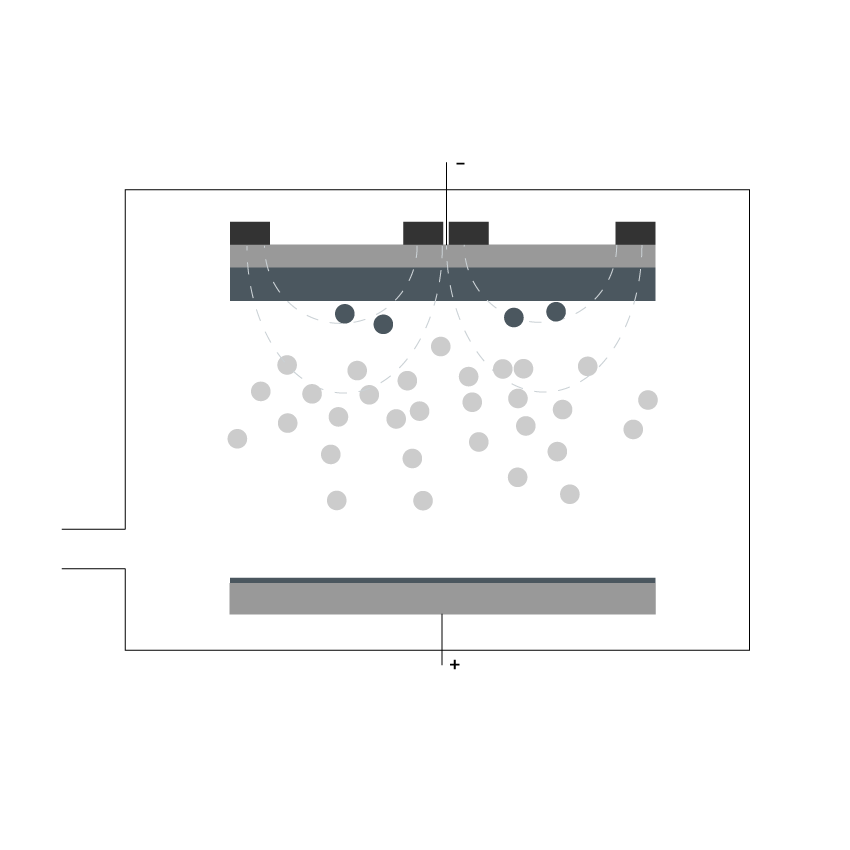

Sputtering

A thick functional layer is deposited using physical vapor deposition (PVD). Magnetron sputtering is a high vacuum deposition technique, where atoms are released from a target material by ion bombardment.

In the case of Nitinol or magnesium, this deposition process allows the fabrication of high-purity films with unique properties, which in many cases cannot be achieved by fabrication routes where material solidifies from a melt. Learn more about the benefits.

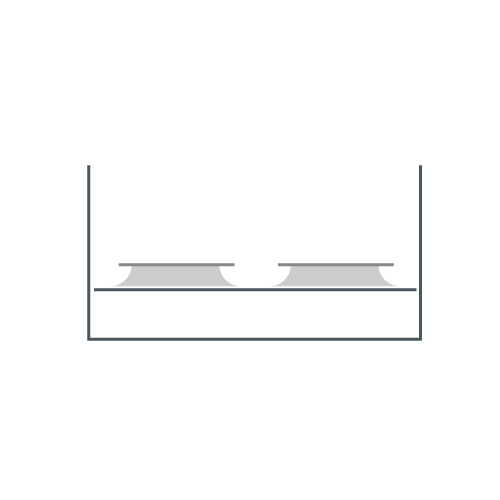

Release from substrate

After sputtering, the thin film product has been shaped according to the initial CAD design. The films are released from the wafer substrate using a sacrificial layer etching technique.Heat treatment

A final heat treatment is required to adjust the functional properties of our Nitinol devices (transformation temperature and mechanical properties). Our heat treatment takes place again in a vacuum environment, so a thick thermal oxide on the surface is avoided.Quality control

According to customer specifications, our quality control checks dimension, transformation temperatures and functional properties of the fabricated devices, up to a complete inspection of all parts, if desired.Shipment

It is important for us to relay the benefits of our fabrication route to our customers. This also includes short turnaround times. In most cases, ACQUANDAS delivers first prototypes in less than two to three weeks from your purchase order.