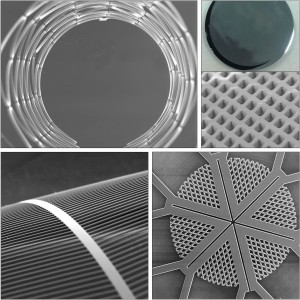

2 dimensional structures

The fabrication of 2D structures is our base technology. Any 2D design can be chosen within the limits of the technology, customized for your product and application. 2D structures are particularly suitable for rapid prototyping. For fast iterations, we recommend fabricating prototypes with different designs on the first run.

2D structures are also suitable for large scale production, where a 6″ wafer area contains a high number of individual components or devices.

You can find out more about the properties of 2D structures in our features and limitations section.

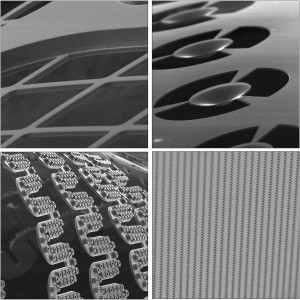

2.5 dimensional structures

2.5 dimensional structures offer a limited degree of freedom into the third dimension. One layer of Nitinol is deposited on top of another layer of Nitinol. Hence, complex geometries can be created, such as flaps attached to a stent-like structure, cavities as reservoirs for micro-pumps or drug-eluting systems, or surfaces covered with micro-needles. In the case of filter systems, certain parts of a Nitinol component can be several tens-of-microns thick in order to give a desired stiffness to the component, while other parts can be thinner and microporous.

2.5 dimensional structures offer a variety of novel design opportunities that are particularly interesting for your next generation medical product.

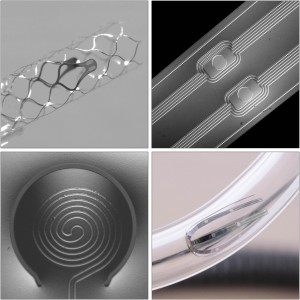

Integrated Functionality

Integrated functionality is a novel field that addresses the need for device miniaturization while simultaneously increasing the functionality of a device. Integrated circuits can be structured on top of a flexible Nitinol structure. The integrated circuits are insulated from the Nitinol structure with a non-conductive oxide.

Thus, different kinds of thin film electrodes on flexible substrates can be produced. Electrodes can be used for sensing, mapping, stimulation or ablation.

A second application of integrated electrical circuits on top of a Nitinol structure is the local activation of shape memory actuators. Instead of directly heating a complete Nitinol actuator, the actuator can be heated locally with low currents, allowing for precise motion control and fast response times due to fast cooling times.

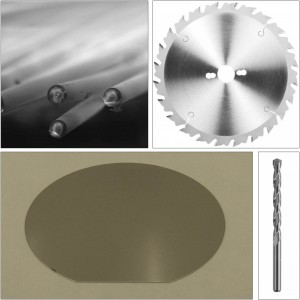

Coatings

Magnetron sputtering can also be used for component coating. Nitinol reveals good damping properties, which makes it interesting for high-quality cutting tools, such as dental drills and sawing blades.